Transformation in Notebook Production, Popularization of Flexible Production Lines for Personalized Customization

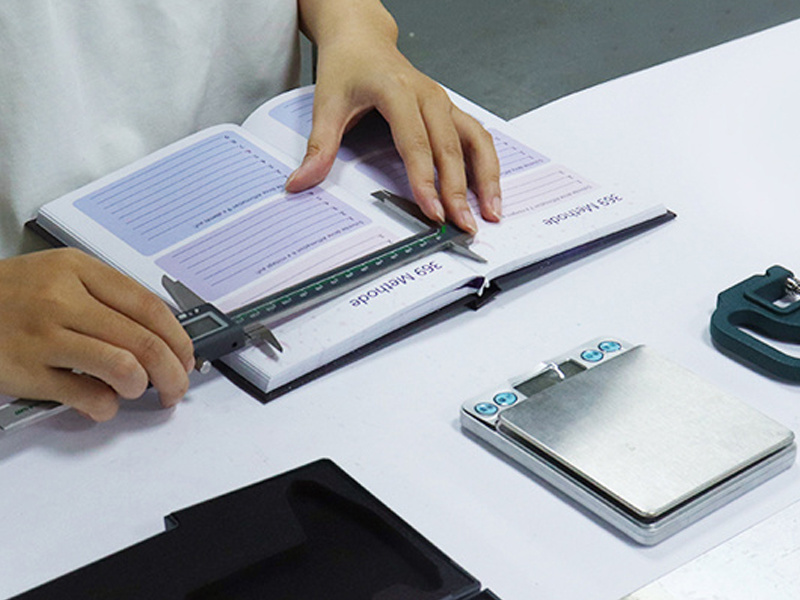

Notebook production realizes full customization of cover patterns and inner page layouts through flexible production lines, supporting small-batch (1-100 copies) rapid production.

Aug 20,2025

Driven by consumption upgrading, notebook production is shifting from "one-size-fits-all" standardization to "personalized for each person" customization. The popularization of flexible production lines enables efficient satisfaction of personalized needs.

The core of flexible production lines is "modularization + digitalization". Traditional notebook production lines rely on fixed molds, requiring 8 hours for plate changing, suitable only for mass production. In contrast, flexible production lines split printing, binding, and cutting into independent modules, linked by digital control systems: cover printing uses digital inkjet technology, supporting users to upload custom patterns (such as photos, illustrations) with a resolution of 1200dpi, enabling switching from file to printing within 30 minutes; inner pages can choose layouts such as ruled, grid, or blank, and even add personalized watermarks (such as names, mottos) through variable data printing technology to achieve "one page, one layout".

The cost bottleneck of small-batch customization has been broken. In the past, the unit price of less than 10 customized notebooks exceeded 50 yuan (including mold fees), but flexible production lines eliminate the mold link. By optimizing processes (such as linking digital printing with automatic binding), the unit price of 10 customized notebooks has dropped to 20 yuan, the same as mass-produced products. Data from a cultural and creative platform shows that in its personalized notebook orders, small batches of 5-50 copies account for 70%, with corporate customization (printing LOGO, corporate culture) and personal commemoration (graduation, travel) as main scenarios.

Technological innovation enhances customization experience. Cover materials support diverse choices: leather (gold stamping and embossing), fabric (embroidery), special paper (UV embossing) to meet different texture needs; binding methods can be self-selected as glue binding, thread binding, or loose-leaf. Among them, loose-leaf customized notebooks allow users to freely add or remove inner pages, adapting to multiple scenarios such as office and study. In a graduation season customization case, the notebook cover printed class photos, and inner pages interspersed with graduation quotation watermarks, with sales exceeding 5000 copies within one week.

In the future, flexible production lines will integrate AI design tools, allowing users to upload keywords (such as "minimalist" "vintage") to automatically generate cover schemes; blockchain technology can be used for number tracing of limited customized notebooks, enhancing collection value, and upgrading personalized notebooks from "utilities" to "emotional carriers".

PREVIOUS: